Hole Dimensions: .040″ to .092″

Deburrs: Choose between “Both Front and Rear” (-B), or “Rear Cutting Only” (-R)

Micro Series Product Specs (PDF)

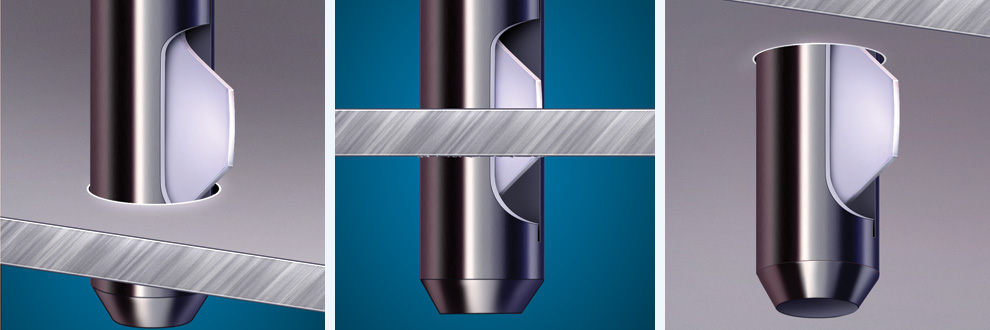

One millimeter, four one-hundredths of an inch (.040”)… that’s how small a hole you can deburr with the E-Z Burr Micro Series Tools.

These tools are strong and durable, just like their big brothers in the rest of our product line. Don’t let their small size fool you, these are the best deburring value available for those tiny troublesome holes.

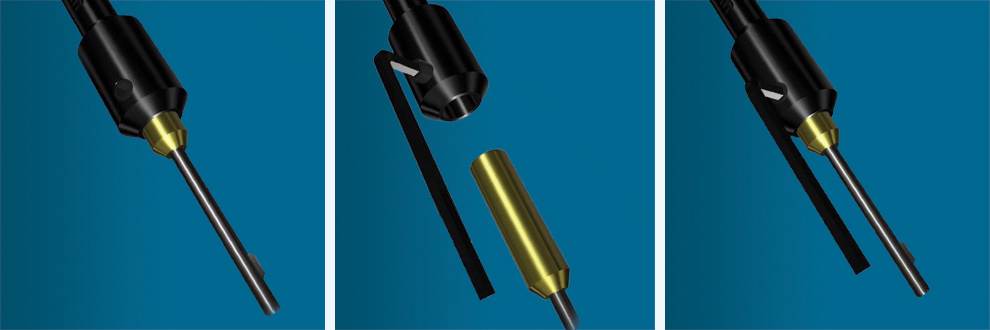

E-Z Burr’s Micro Series offers a patented two-piece construction consisting of a convenient cartridge (with arbor & blade) and a holder. All cartridge sizes fit into the one standard holder, you just clamp it in with a setscrew and you’re deburring small holes instantly. You can also replace the cartridge in seconds while the micro tool is still in the spindle, so you won’t have to handle or lose any miniature parts. In addition, you can deburr hundreds of micro holes before the cartridge needs to be replaced. While we always recommend using the holder, you can also just simply hold onto the .156” diameter brass cartridge sleeve.

Industries who may benefit from our Micro Series include medical and dental, firearm manufacturers and electronics manufacturers. These micro deburring tools are used on all materials and can be run in a CNC or a hand drill. We even offer a rear-cutting-only size for .033” diameter holes, although that is a special make item.